|

|

Shutdown at Fermilab by Kurt Riesselmann When it comes to shutdowns of the accelerator complex at Fermilab, the definition of the American Heritage dictionary is quite misleading.

For accelerators, shutdown time is the time of rejuvenation.

"The coordination is going really well," said Bob Mau, Head of Accelerator Operations and overall coordinator of the shutdown. "We have to share key resources, from equipment to manpower to space. Nobody wants to be left out." The ten-week shutdown, scheduled to end at the middle of November, allows for the following projects to proceed:

"We observed a coupling between the vertical and horizontal magnetic fields that was ten times worse than expected," said Mike Syphers, head of the Accelerator Integration Department. "During a test, pure horizontal oscillations in the beam would quickly turn into pure vertical oscillations, something that couldn't be explained with standard alignment deviations."

Independently, Dave Harding and his group in the technical division suspected a systematic problem when they checked the support bolts of 18 magnets and compared the measurements to data sheets recorded in 1980. "The placement of the superconducting coil relative to the iron frame is important," Harding explained. "We found that all coils had shifted in the same direction, by about five thousandth of an inch." The tiny shift explained the adverse coupling phenomenon observed by Syphers and his colleagues. To fix the problem three crews of technicians from the Technical Division are spending the shutdown in the Tevatron tunnel. They will correct the coil positions by adding tiny shims, about 100 microns thick, to the support bolts. "During the production of the magnets more than twenty years ago, we did this nearly a thousand times," Harding said. "We even have ten thousand shims left over from that time. But with the magnets installed in the tunnel, it is a big challenge to get to the bolts on the back side. Our technicians are essentially working blind-folded, hanging across the magnets." Each team has practiced the task on an old magnet. Over the course of the shutdown the crews will fix 106 magnets.

Tevatron:

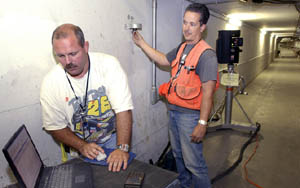

Since the beginning of the lab, the Fermilab alignment group has helped scientists to provide particles with the smoothest ride possible. During the shutdown, the group will greatly improve their alignment capabilities by installing TeV Net, a new surveying network in the Tevatron tunnel. "We plan to achieve a never-imagined accuracy," said Bob Bernstein, who leads the alignment group. "We expect the network to give us a precision of ten thousandths of an inch. We will be able to monitor whether the path in the tunnel shifts over time far better than we ever have before." The network relies on 35 deep-rod monuments that reach more than 40 feet into the ground. Their locations are known to within 1.5 mm, using line-of-sight laser-ranging measurements and satellite-based GPS technology. Twenty-three people, including four technicians from the Particle Physics Division, three contractors and two surveyors from the Stanford Linear Accelerator Center, are working on transferring the precision coordinates from the monuments into the Tevatron tunnel, where they are installing a network of reference points. The surveyors are measuring the location of every Tevatron magnet and will use these measurements together with the network to improve the under-standing of the Tevatron's particle road.

NuMI: "Among the first things to be installed are three Lambertson magnets," said Rich Andrews, who oversees the beam line installation. "These devices will divert protons from the Main Injector ring into the NuMI beam line."

The first stretch of the NuMI beam line will tightly fit between magnets of the existing Main Injector and the Recycler ring. "There is a huge amount of infrastructure to work around," said Rick Ford, Andrews' deputy. "It's quite a challenge. On the order of 60 people will be involved in the underground work during the shutdown, including 20 ironworkers from a contractor. Our first task is to install a monorail for cranes that will then allow us to properly position the magnets." The NuMI group aims to complete the installation of the major beam elements of the first 550 feet of the NuMI beam line before the end of the shutdown. Contractors supervised by lab personnel will install 29 magnets and survey workers will carry out an initial, rough alignment. Final alignment as well as the installation of the last NuMI beam line components will take place in 2004.

Recycler: Water vapor inside beam pipes is one of the worst enemies of beam quality. As particles are racing through an accelerator ring, every encounter with a water molecule or other large obstacle diminishes the intensity of the beam. To combat the enemy, accelerator experts use sophisticated vacuum pumps to suck out as many impurities as possible. This, however, doesn't eliminate gas particles attached to the surfaces of vacuum pipes and pumps—particles that slowly diffuse into the vacuum. To remove the surface contamination, technicians heat vacuum equipment to about 250 degrees Fahrenheit and let it bake for several days.

"We've divided the Recycler ring into six work areas," said Sergei Nagaitsev, head of the Recycler department. "Each area is assigned to a bake-out team of four people, led by a skilled vacuum technician." The technicians use special heating tape, which is interlaced with electrical wire, to heat a set of pipes and vacuum pumps for four days in a row. Because the heating consumes a large amount of electrical power, only a few vacuum sections of the Recycler can be treated at a given time. The project will take ten weeks to complete, and it will determine the overall length of the shutdown.

Booster: In the coming weeks technicians will install—among other things—four new large-aperture magnets and a new collimation system. The new equipment should allow the Booster to handle higher beam intensities without increasing beam losses. In addition, two new prototype radio-frequency (RF) accelerator cavities will be installed to test their viability for a possible future upgrade. "The RF project is only possible because a large fraction of the machining was done at machine shops at a number of universities involved in the MiniBooNE and NuMI experiments," said Eric Prebys, head of the Proton Source Department. "This was an excellent example of successful collaboration between the lab and universities." As with all other projects carried out during the shutdown, Prebys doesn't expect to see improvements on day one after the shutdown. "The commissioning process will take some time," he said. "I'm estimating about two to three months until we take full advantage of all the improvements." On the Web:

Fermilab Beams Division

Proton Source Department

Main Injector Department

Tevatron Department

NuMI Project |

| last modified 10/1/2003 email Fermilab |

FRLsDFx9eyfrPXgV