|

|

SiDet: The Next Generation Young Physicists Make Important Contributions to silicon detector production for Run II.

by Mike Perricone They work in the world's biggest facility of its kind, but some of the components they handle are scarcely bigger than the head of a pin, and the measurements they make are equivalent to fractions of the width of a human hair. They run innumerable tests on the components they're building, and then they run more tests. If they cough when their masks are off, they can ruin days of work. Despite their painstaking efforts, many components still wind up as scrap or practice projects, while assemblies being successfully completed are stored in sealed plastic bins filled with dry nitrogen gas to forbid moisture. This is life at Fermilab's SiDet Facility, producing the silicon detector technology for the next generation of particle physics at the CDF and DZero detectors. The key work at SiDet is being done by the next generation of physicists: postdocs who are designing and building detector components, instead of adding their names to research papers that will get them noticed and appointed to long-term positions. "Since postdocs have a limited contract, they have to apply for the next job after three years or so," said Frank Lehner, a postdoc from Germany. "The thing that counts most in the application process is scientific achievement." Lehner is working on the 90-degree double-sided detectors used in the barrel surrounding the beamline. These are the last and most complex of the five types of silicon wafer detectors to achieve "proof of principle," meaning that the prototype definitely works. "I came to Fermilab with the intention of doing Run II physics," said Lehner, who arrived in 1998 after working at DESY in Germany, and achieving his Ph.D. from the University of Hamburg. "It was obvious to me that the upgrade project has to be finished first before one can start taking or analyzing data and doing physics. I was fully aware of that point, and basically, I like the hardware work which I am doing." The postdocs' reward must stem from their work, and from knowing they are enabling the pursuit of new discoveries in Run II, the collider run of the Tevatron that will kick off the next millennium.

"Yes, physics analysis probably is more rewarding for a postdoc than getting the production started for Run II," admitted Peter Van Gemmeren, also from Germany, who graduated from the University of Siegen, and received his Ph.D. from the University of Mainz for work on the ALEPH experiment at CERN in Switzerland. "But without a very big effort from everybody involved, we wouldn't be able to get prepared for Run II," continued Van Gemmeren, who worked on the fourth detector type to achieve proof of principle. "This (production) also has the advantage of involving all different kinds of physics work: first, planning and developing a detector, or a single component, building the prototype and testing it. Then getting the production started and writing the software tools, for example triggering or reconstruction, for each detector component. Then taking data and designing an analysis. And at the end, of course, publishing a result." Fitting into the big picture works fine with the sunny outlook of Maria Roco, a Philippine native who did her graduate work at the University of Iowa and her Ph.D. thesis on the ZEUS experiment at DESY. "It was not a hard choice for me, and I've been enjoying myself," said Roco, who for the last two years has worked on developing the Silicon Microstrip Tracker for DZero. "These production tasks are very important to the upgrade if DZero wants to have a working detector to do all the great physics it wants to do in Run II."

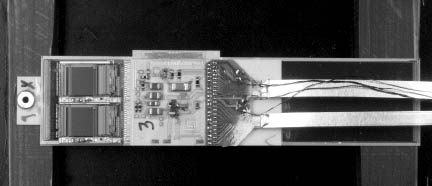

Roco and Cecilia Gerber are building the "ladders" that will go onto the SMT. Roco has been coordinating the assembly, production and quality testing of the nine-chip, double-sided ladders, while Gerber has been doing the same for three-chip, single-sided ladders. These rectangular devices sound simple, but they must be nearly weightless, bonded to readout chips smaller than a dime, and must precisely record particle paths during intense bombardments of particles from proton-antiproton collisions.

Silicon detectors are extremely accurate and extremely hardy. CDF has used silicon detectors for years, in conjunction with a magnetic field in close proximity to the collision point. DZero will be using its first generation of silicon detectors, with its first magnetic field close to the collision point. "What we do in high energy physics is like recording paths of pieces flying away from a car explosion, and then trying to figure out just what kind of car it was," said Bill Reay, who with Ron Lipton is a co-project manager for the DZero silicon efforts at SiDet. The goal is to identify particles traveling at the speed of light, moving only millimeters between birth and decay. With their unequalled accuracy (on the order of 1/10 the diameter of the human hair) and durability, silicon detectors can be placed right near the point of a particle collision where new particles are made, and used to track the products of decays that begin only a few millimeters away from the collision point. Individual components are assembled into detectors at SiDet, housed in a former bubble chamber building plus additions called Labs B, C and D, all located out at the end of the fixed target area. Detectors can be rectangular or wedge-shaped, depending on their placement into barrels or disks within the overall detector assembly. Segments called "barrels" (containing hundreds of ladders) will be located in a carbon-fiber tube resembling a cylinder about four feet long and a foot wide. Surrounding the beam line, this cylinder is the heart of CDF and DZero, those massive, 5,000-ton, forty-foot particle detectors that roll into the collision halls of the Tevatron. The array of tiny detector and readout chips, and the cables emanating from them, will provide some 900,000 channels of information and about 90 percent of the data collected from the entire detector. Reading out such vast amounts of data is not an easy task. New postdoc Aurelio Juste and Fermilab associate scientist Marcel Demarteau, developing DZero's complex data acquisition system, have reached the point of a single mistake in every hundred-trillion bits of data. They're not satisfied; they want to do ten times better. There are three types of barrel detectors providing the mountains of data: single-sided detectors with strips running parallel to the beamline; two-degree double-sided detectors with strips on a second side mounted at a two-degree angle to those on the first; and 90-degree double-sided detectors, with strips on the second side mounted at 90 degrees to those on the first. The first two types are in production; the 90-degree detectors will reach production stage in September. Interspersed throughout the barrels are F-disks composed of detector wedges, resembling pizza slices with a bite out of the point. These are mounted perpendicular to the beam line and measure forward-going particles. Out beyond each end of the central cylinder are two H-disks, completing the measurement of forward-going tracks. They’re similar in shape to the F-disks, but much larger. Eric Kajfasz, a staff member from the Centre de Physique des Particules de Marseille (France) is an old hand at silicon detector production. From 1992 to 1995, he worked on R&D, construction, bonding and testing of the ladders for the two barrels of the silicon microstrip detectors, then worked on the commissioning of those detectors first used at CDF (called SVX1). He returned in February 1998 as a DZero collaborator working on the next generation of silicon detectors. "With SVX1 we only had to build two barrels with a total of 96 ladders," he recalled. "The new DZero detector has six barrels, 12 F-disks and four H disks, with a total of 672 ladders and wedges. That's an order of magnitude more production than for SVX1—but without an order of magnitude more people working on it." Just an order of magnitude more effort from those like Gerber, Juste, Kajfasz, Lehner, Roco, Van Gemmeren and many others. "Without the work of these young people," Reay said, "this project just wouldn't get done."

|

| last modified 8/6/1999 email Fermilab |

FRLsDFx9eyfrPXgV