|

Fermilab Shutdown Report

8/24/07 – 8/31/07

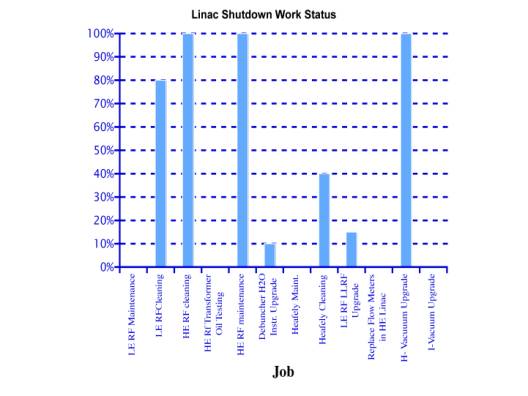

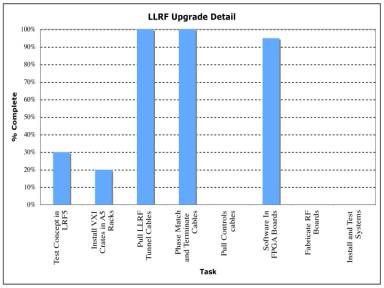

LINAC

- All work on Schedule

- LLRF Upgrade

- The Neutron Therapy Facility is treating patients during the evening

Booster

Electrical Work:

Water work:

- LCW water work in the Booster West Gallery

- Most of the work is concentrated on the north side of the gallery

- Nevertheless, one must use caution while walking down the galleries and watch out for workers

- 4” copper pipe mounted on the wall and progressing with the BRF manifold

- Next week: Proceed with the BRF manifold upgrade and pressure test of the 4” line

- Tunnel water work:

- 80% filtration system complete (L2, L4, L11, L14, L16, L23)

- 50% of them have the 0.5 micron filter installed

- Next week: Connect water to the correctors. Finalize filtration system at L16

- CUB

- Booster de-oxy system is coming along

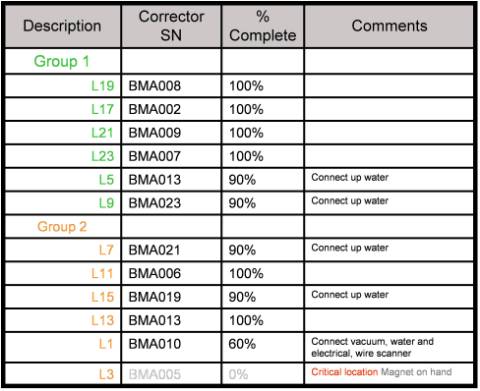

- Corrector installation

- Number of new correctors in the tunnel: 11

- L19,L17,L21,L23,L15,L9,L11,L13,L5,L7,L1

- L1 is not a standard installation

- It has been fully surveyed

- Except for L1, all correctors are electrically connected

- Working towards powering correctors in the tunnel

- Booster vacuum slowly recovering

- Next week

- Continue monitoring vacuum

- Continue L1 installation

- Keep up efforts for energizing the correctors

- Additional Activities

- Sink hole is still a concern

- Sumps reconfigured in preparation

- For Booster East Utility Yard

- Excavation

- Expect to start hand digging today

- RF maintenance work is proceeding well

Antiproton Source

Mechanical

- Leak Check (4)

- AP3 not recover from outage

- Finished checking D/A, A40, A30

- D:ESEP, A30 IP fixed

- D:ISEP Shielding

- Ion Chamber removal

- Deb DCCT motorized stand

- D:EKIK ceramic tube

- AP2 Water Hose Replacement

- Leaking LQA

- Replaced leaking Deb Sextuple

- SMA water leak

- 4 water leaks to fix

Target Station

- Water Systems (2)

- Temperature Monitoring (2)

- Target Rotation

- Storage

- SEM Module

- LVDTs

- Sample Retrieval

- Lens motion

- Air Exhaust Stack

- 10mm-2 into transformer

- 10mm-3 into transformer

- Lens replacement

Cryo

- Valve Stem replace

- Leak Check (1 of 2)

- LN2 transfer line maintenance

Cooling Systems

- Deb 3&4 Trans Notch Filters

- Deb Double Notch Filters

- Core 4-8GHz Equalizer

- TWT balance & trip points

- Stacktail Filter 3 cable change

Electrical (Pbar & EE Support)

- Shunt Move

- Shunt Repairs (6)

- PS Maintenance

- Lens SCRs

- Regulation Electronics

- Ion Pump maintenance

- Deb Shunt re-arrangement

Other

- Interlocks/Safety System (3)

- Repair cathodic protection

- Dirt holes under buildings

- Dripping from tunnel ceiling

- DCCT calibration

- Baking System checkout

- RF & TWT filters maintenance

- Lights Checkout

- Acc BPM repairs

- Activation Survey

- Finished AP1, Acc, Deb, AP2

- Inductance checkout

- PM ODH Fans & Sumps

- Tunnel Wireless

- Install Leak Detector

- SEM maintenance

- Clogged sump line – Transport

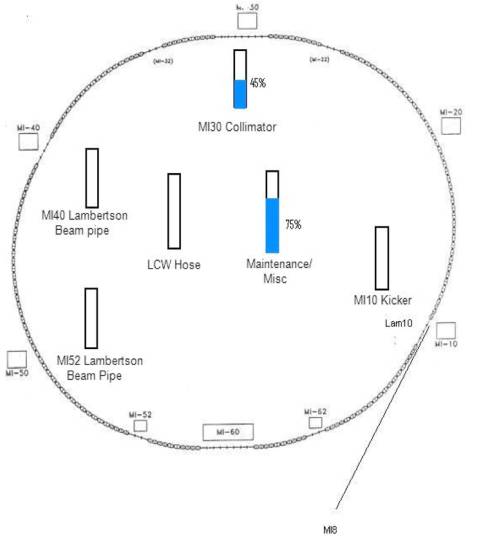

Main Injector

Maintenance

Recycler

- Finished or underway

- New DCCT section installed, leak checked and under vacuum since Wednesday last week; pumping down

- DCCT section has been aligned

- Will probably be baked starting in a week or so

- V303 moved

- H308 moved

- Need to check ALL LEP dipole positioning with respect to Beampipe

- STC tank 7 leak check underway

- Second attempt has been made; detected air but found no external leak so far

- Trombone additional quadrupoles installation issues

- HLRF cooperation

- Finished: 601, 602, 603, 604, 605, 606, & 607

- Underway: 608

- Wait on 609 location

- Added support to old DCCT

- Bulk supply upgrade (on-going)

- DCCT cable connected

- Stochastic cooling: Photodiodes aligned

- Pelletron Status

- All maintenance items have been finished

- Tank was closed yesterday

- Today:

- Turn on HV and condition the gas side

- Work on camera timing

- On the list

- Magnet moves and survey /alignment

- Elevation survey before and after collimator installation

- Measure Z coordinates of Quadrupoles in trombone section

- Reference to the surveyed elements

- Electrical connection for new quadrupoles

- Field check for new quadrupoles

- 800 transfer line vacuum work

- Vacuum maintenance

- Kicker repair; timing verification

- TOR330 repair

- BPM calibration

- Diagnostics maintenance

- MI-21 SA camera/TV repair

- Laser link vacuum maintenance

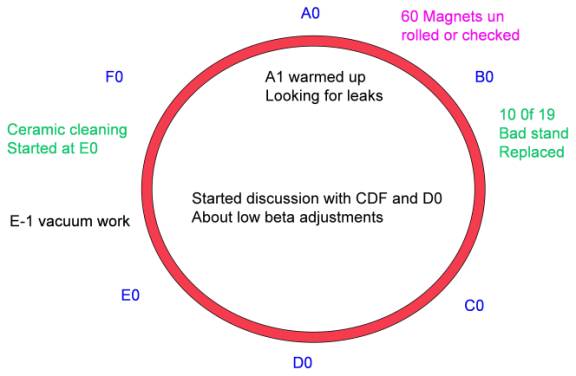

Tevatron

Tevatron status as of August 31

SwitchYard

Continuing with maintenance work. Installing quadrupole magnets in the F3 Manhole.

NuMI

- Completed early maintenance of target pile chiller

- Drain cleaning complete in Decay Pipe Walkway, Target Hall, Pre-Target, and Carrier regions

- Developed to look for leak in Horn 2 RAW suction line

- Developing plan to inspection upstream Decay Pipe Window

- Target Pile Dehumidification Installation Project (30%)

- Installation 220’ insulation on chilled water pipe in shaft

- Installing 2” electrical conduit in upper labyrinth

- Completed installation of chilled water piping @ bottom of shaft

- Installed 40’ of 4” chilled water pipe in upper labyrinth

- Completed installation of 4” chilled water pipe hangers in T-Hall

- Installed 420’ of chilled water piping in the T-Hall

- Installed 200’ of 2” conduit in the Target Hall

- Developed final layout for duct work to Munter dehumidifiers

- Received the evaporator, chiller and dehumidifier platforms

MiniBooNE

Work completed this last week.

- Reverse Horn Polarity

- Reverse polarity of horn power supply

- Test horn

- Retrieve Corrosion Tabs from 25m Absorber (27/28Aug07)

- No obvious corrosion to stainless steel

- Also inspected spare lifting lug – no apparent damage

- Change RAW DI Bottle (50%)

- Dry out horn (09Aug07)

- Check Leakage Current on Ion Pumps

- Power Supply Maintenance

- Toroid Work

MTA Beamline Installation

- Shielding underneath hatch area

- 08/27 Floor underneath the hatch area has been leveled to aid the shielding wall installation

- 08/30 Crane/Iron Workers returned to the job site

- Lifted left over material and unneeded equipment

- Started restacking shielding wall yesterday!

- Next week:

- Finish the wall

- ETC: 09/05

- Electrical Work

- Cable tray installation 100% complete

- Cable pull started and is progressing well

- Start with load cables – 30% complete.

- Next week: Continue with cable pulling and termination

- Alignment

- Crew was available this week to finish the network

- Crew assisted on checking stationing of some questionable magnets

- Next week: If schedule permits, start roughing alignment late in the week (or maybe early week 6)

- Core Drill

- Core drill of 3 blocks was successful performed yesterday

- Some other cuts were also done in order to get the right amount of shielding blocks for the new wall

- Magnet Installation

- 4 magnets remain to be full stationed

- Installation on hold until shielding wall is complete

- Next week: Resume installation after completion of the wall

- LCW work

- LCW connected to Booster 95 header

- Good progress with the long straight sections in the tunnel

- Both supply/return 2” copper piping installed along the wall

- Contractors are approaching the cross over the beam lines

- Next week: Continue with the 2” copper piping installation

- Vacuum work

- Making as much progress as possible with the spool pieces and flanges.

- Gathering parts for the ion pump stands

Collider Detector at Fermilab

- Silicon cooling leak repair

- Worked on east most of the week

- Started on west yesterday

- Other shutdown work ongoing

- Power outage at B0/CDF trailers

- 0800-1600 for both

- Experimental power off until Wedensday morning

- Will start shutting stuff down Monday evening

D-Zero

Work continues. Next week we will clean the high voltage

Alignment

Completed Jobs

- Recycler Task Manager: Oshinowo

- 5527 Optically align Recycler DCCT after installation. Date: 8/13/2007 Complete

- Tevatron Task Manager: Bocean

- 5494 As found low beta quads and separators at B0 Date: 8/06/2007- 8/08/2007 Complete

- 5495 As found low beta quads and separators at D0. Date: 8/09/2007- 8/14/2007 Complete

- 5498 Measure rolls on 111 dipoles and quads in Tevatron (48) Complete

- 5501 Un roll D16-1 quad when D-1 is warmed.(As Found) Date: 8/13/2007 Complete

- 5591 As Founds of the Roman pots at D0 4 of 6 Date: 8/13/2007 85% Complete

- 5598 A0 dump as found (no request for this job) Date: 8/23/2007 Complete

- 5594 As found Schottkies, Separators and Beam pipe at A17 s Date: 8/24/2007 Complete

- 5572 As found and re survey kicker replacement at F-17. Date: 8/28/2007 Complete

- 5506 As found crystal collimator at E0. Date: 8/28/2007 Complete

- 5506 level run through Tevatron tie rods. Date: 8/29/2007 Complete

- Booster Task Manager: Oshinowo

- 5534 Align 24 Booster Corrector Magnets.( Long 19 Long 17 ) Date: 8/13/2007 Complete

- 5534 Align 24 Booster Corrector Magnets ( Long 21 Long 23 ) Date: 8/14/2007 Complete

- 5534 Align 24 Booster Corrector Magnets ( Long13 Long15 ) Date: 8/20/2007 Complete

- 5534 Align 24 Booster Corrector Magnets ( Long 11 Long 9 ) Date: 8/21/2007 Complete

- 5534 Align 24 Booster Corrector Magnets ( Long 7 Long 5 ) Date: 8/23/2007 Complete

- 5534 Align 24 Booster Corrector Magnets ( Long 1 ) Date: 8/30/2007 Complete

- Main Injector Task Manager: Oshinowo

- 5563 AS found survey of Quadrupoles at 400, 402, 404 and the three Lambertson. Date: 8/13/2007- 8/15/2007 Complete

- 5554 307, 308 Collimators: Base plate survey Date: 8/16/2007 Complete

- 5554 307, 308 Collimators: Set travel and limit switches Date: 8/22/2007 Complete

- 5596 Magnet 614 had to be moved please realign. Date: 8/23/2007 Complete

- 5562 The beam pipe on the downstream side of the MI40 Lambertson. Date 8/29/2007 Complete

- CMS Task Manager: Oshinowo Field Crew: O’Boyle.

- 5516 Survey the CMS F-pixel Half cylinder +Z2 in the Lab C Date: 8/09/2007 Complete

- D0 Task Manager: Oshinowo

- Stickmike survey of Muon system prior to opening of detector. This will include both CFs and EFs. Date: 8/06/2007 Complete

- 5524 VStar or Laser Tracker survey of North/South EF pedestals with respect to the sidewalk monuments. Date: 8/07/2007 Complete

- 5592 Elevation run in D0 before machine is opened. Date: 8/06/2007 Complete

- Linac Task Manager: Oshinowo

- 5468 Stake out the MuCool beamline component locations in the Linac and MuCool Test Area (MTA). Date: 8/08/2007 Complete

- P-Bar Task Manager: Oshinowo

- A4Q10 (LQA in Accumulator) has a water leak. An "as found“ Date: 8/09/2007 Complete

- 5595 An Accumulator multipole magnet (SMA) has developed an internal Date: 8/23/2007 Complete

- 5488 Alignment A4Q10 (LQA in Accumulator) has a water leak. Date: 8/30/2007 Complete

- Nova Task Manager: Oshinowo

- 5475- Stake out new Recycler injection line (MI10) Date: 8/27/2007 Complete

- MTA Task Manager: Oshinowo

- 5469 Vertical check of the MuCool beam line components. Date: 8/29/2007 Complete

Next week’s schedule of work

- Tevatron Task Manager: Bocean Field Crew: Bradford, Adkins, J Wilson.

- 5499 Measure and re align 29 dipoles and quads that have new stands. Date: 9/04/2007- 9/07/2007

- As found TEL1 in transfer hall. Date: 9/05/2007

- As found TEL2 in transfer hall. Date: 9/06/2007

- Booster Task Manager: Oshinowo

- 5534 Align 24 Booster Corrector Magnets Date: 9/04/2007

- Main Injector Task Manager: Oshinowo

- 5554 4 collimators in the Main Injector at the 301, 303, 307, and 308 locations. Date: 9/04/2007-9/07/2007

- Nova Task Manager: Oshinowo

- 5477-Stake out new Recycler RR30 quad positions for the Nova Project Date: 9/06/2007

- 5476-Stake out new Recycler extraction line (MI30) for the Nova Project Accelerator upgrade. Date: 9/07/2007

- MTA Task Manager: Oshinowo

- Shoot MTA shielding blocks after re-stacking them underneath the hatchway area.

- 5469 Rough alignment of the MuCool beam line components

- CMS Task Manager: Oshinowo

- 5516 Survey the CMS F-pixel Half cylinder +Z2 in the Lab C Date: 8/06/2007

- CDF Task Manager: Greenwood

- CMS Task Manager: Oshinowo

- 5516 Survey the CMS F-pixel Half cylinder +Z2 in the Lab C Date: 8/06/2007

- ILC Task Manager: Bocean Not Scheduled

- P150 Task Manager: Oshinowo Late Request

- 5593 We had to move several magnets and multiwires to make up the ends on the cans for vacuum connections. They are as follows: The multiwire cans at 708 and 710. B2 magnets at the interface of 710 - 711 and the interfaces of 709 - 710, the serial #'s are BDM 883-1 BDM 835-1 BDM 879-1 and BDM 397-1. Date: 9/07/2007

Alignment and Metrology Home page

Mechanical

Janitorial work in the tunnels continues.

Cryogenic System

Tevatron at LN2 temperature except A1, C4, D1, and E1 at room temperature

- Tunnel magnet cryostat vacuums at A15, A25, and D35 regions are of concern.

- D-Zero Cryo online with TeV Cryo Compr discharge/suction headers due to pond work

- 3 FRIG Mycom compressors (plus CDF) running with helium precooled to LN2 temperature flowing through magnet strings

Cryo Operations

- 3 FRIG Mycom compressors (plus DZero & CDF Cryo) running with helium precooled to LN2 temperature flowing through magnet strings

- CHL helium inventory management system operating (Tank Farm, Helium Purifier, A0 GHe Recovery) and Tank Farm has been purified; the helium losses are normal

- CHL Nitrogen Reliquefier plant off and LN2 supply dependent on vendor deliveries to CHL LN2 Dewar tanks; deliveries are fine

FRIG Maintenance

- 10 of 13 wet expander flywheels have been replaced

- 12 of 26 wet/dry expander overhauls of cold ends are completed (A1 thru C2, plus the Antiproton Source)

- Various vacuum, instrumentation, and controls maintenance continuing

CHL Maintenance

- CHL helium inventory management system operating on clean Helium Tank Farm, though A0 GHe Recovery being vented due to CHL Main Helium Purifier plugged after 8-hour planned power outage. Currently CHL operating Screw Compressors on Mobile Helium Purifier while Main Purifier is being warmed up to room temperature for derime

- Coldbox-1:

- Charcoal Adsorber east unit regeneration at high temperature completed and now cooling down

- Nitrogen Reliquefier plant maintenance in progress:

- Marley Cooling Tower refurbishment almost complete

- Rotoflow compressor aftercooler tube bundle was replaced

- TSI compressor 3000 hp motor replaced and newly installed to be test run

- Various compressors and facility maintenance in progress

Current Operations

- Pbar Helium system (Debuncher and S/C Notch Filter tank) will be cooled down to LHe temperature next week for testing; FRIG Compr system has been purified past several weeks via CDF and D-Zero Helium Purifiers while they were online with FRIG Compr suction/discharge headers

- CHL Nitrogen Reliquefier plant off and LN2 supply dependent on vendor deliveries to CHL LN2 Dewar tanks; deliveries are fine

- CHL runs on a fire hose for ICW

Controls

This Week

- AD Windows Web Server Updates completed

- CAMAC Front End SLD Updates completed

- MADC II Updates continued

- Routine maintenance

Next Week

- Wednesday 9/5/07

- Linux File Server Upgrade

- Console Apps likely down ~4 hrs.

- Thursday 9/6/07

- BSSB version 8.8 Update ~1/2 hr.

- MI CAMAC Link Reconfiguration

- Loss of MI-30 CAMAC Communication ~1hr.

- Console Node OS Upgrades

- Individual console nodes unavailable ~1 hr.

Get Requests In Now

- Hardware you want to use may not be readily available

- New infrastructure (links, clocks, networking) takes time

- Work has to get scheduled

FESS

Casey’s Pond

- OPERATING 3 – 100HP PUMPS & C-4.

- FLOWS/PRESSURE STABLE.

- WILL CONTINUE INTO/THRU NEXT WEEK. (C-4 Power Outage on 9/8/07?)

- ICW FLOW METER WIP

Poles

- 18 of 19 poles installed.

- Projected completion is ~ 9/11/07 – ahead of schedule [weather ?]

- TENTATIVE POWER UP ON 9/29/07

TeV pond silt

- SECTORS A/B/C/ COMPLETED. D/E/F REMAINING.

- SUCTION SCREEN EXTENSION WIP [~ 30 REQUIRED].

Sink Holes

- BTE – PRELIMINARY INVESTIGATION/HAND DIG & REPAIR STRATEGY WIP FOR SUMP DISCHARGE LINE BREAK.

- AP-0 – LOCATED SUMP DISCHARGE LINE BREAK/HOLE AT TUNNEL LEVEL

Other Jobs

- CDF ICW VALVE BY-PASS WIP. TEMPORARY HOSE CONNECTION IN PLACE AT CHL.

- CUB #3 CHILLER[55LCW] – 15 TUBES PLUGGED

- MAINTENANCE CRAFT STANDARD STATUS CHART.

Safety

- Safety System Status

- Upgrade M02 - M05 Enclosure Interlocks 35%

- Upgrade Main Injector PLC Code and replace PLC Batteries 35%

- Replace Safety System DEC talk with ATT Natural Voices 30%

- Linux kernal 2.4 to 2.6 upgrade to Safety Data Acquisition System 25%

- Upgrade Meson Area Oxygen Monitors 0%

- Install Radiation Monitor Cables for the Muon Test Area 0%

- Replace Pbar Vault Key Tree Door Latches & add status LEDs 0%

- Route Key Tree release signals from MCR to Meson 100%

- Route Key Tree release signals from MCR to Meson 0%

- Prevent Injuries

- Use proper body mechanics when lifting.

- Utilize PPE to protect from injuries

- Be aware of surroundings

- A successful shutdown is getting our work done safely

Accelerator Update Archive

More Information

For Tevatron luminosity charts and the current status of Fermilab's accelerators and detectors (live!), please go to Fermilab Now.

Comments and Suggestions

What do you think about the Accelerator Updates? Please send comments and suggestions to: accelupdates@fnal.gov.

|